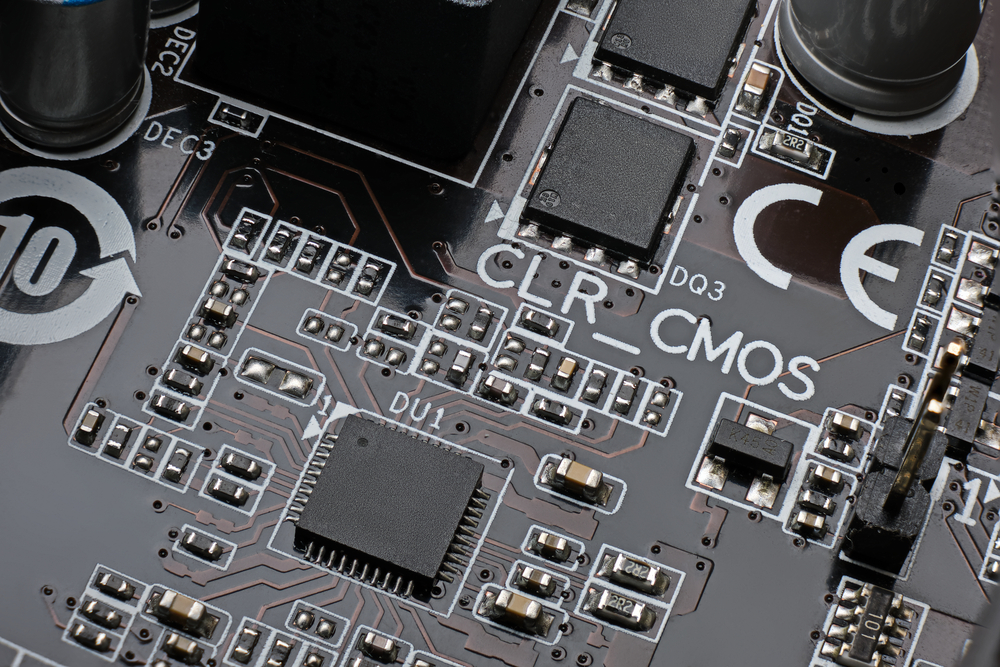

Vitrobond® SMT Epoxy or Surface Mount Adhesive is mainly used for mounting and bonding surface mount devices (SMD) to the printed circuit board by way of high-speed dotting or screen printing process of the adhesive.

These SMT epoxies from the Vitrobond® range have high green strength, it can prevent the SMDs from skewing during inline movement and the solder or double-sided reflow process at 250°C temperature environment.

The SMT epoxy has good thixotropy index that gives the dispensed dot size a controlled spherical shape from slumping before the placement of SMDs to the printed circuit board. It is fast cure at 150°C for less than 2 minutes to obtain good die shear strength.

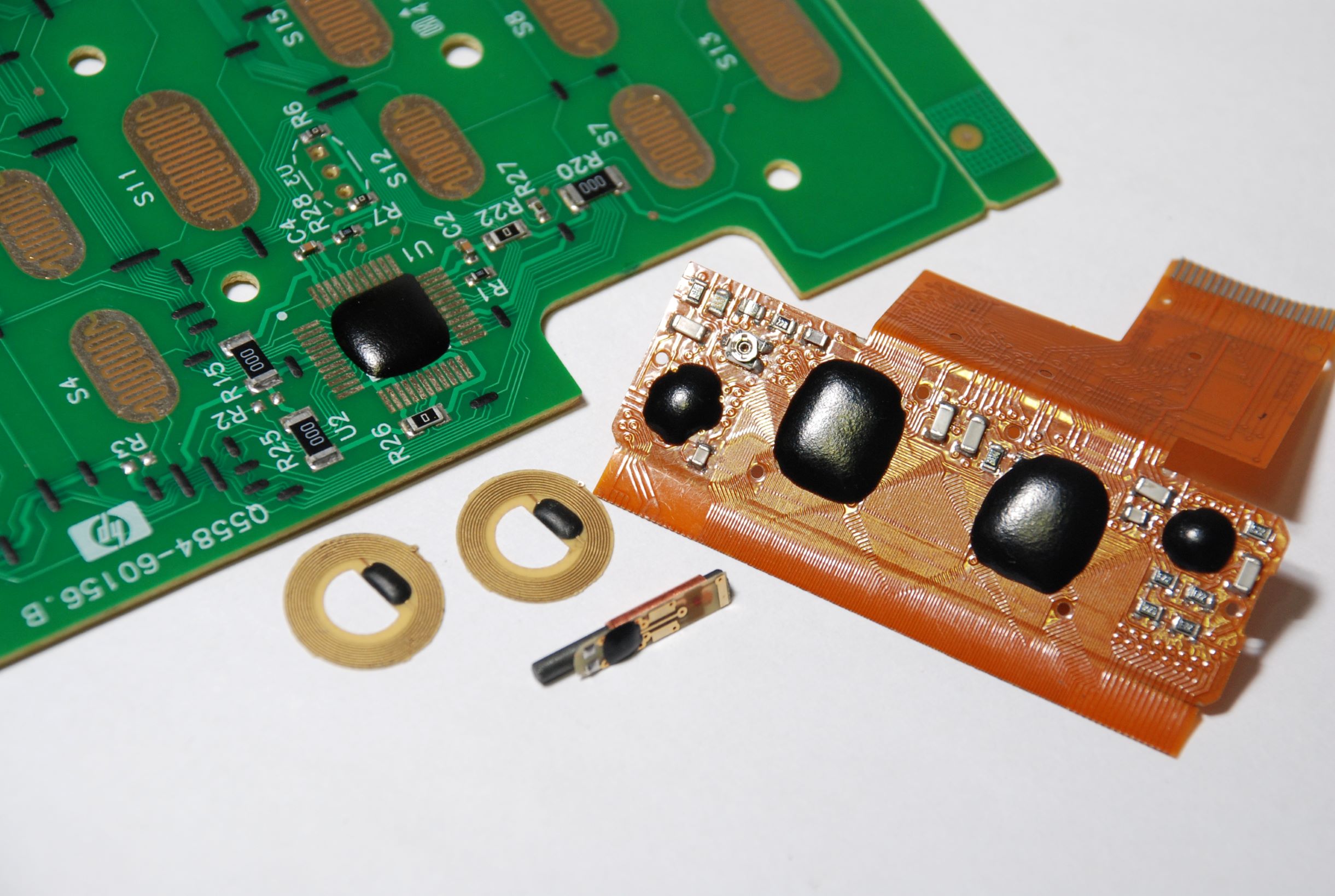

Vitrobond® one component heat cure glob top epoxy (commonly termed as Chip-On-Board - COB epoxy) is regularly used by the printed circuit board assemblers or semiconductor players to encapsulate bare silicon chip after attachment and wire bonding process.

The primary purpose is to protect the silicon chip or bare die from environmental exposure that may potentially short circuit it and also to prevent any form of corrosion or oxidization that may set in during the operation of the devices.

Vitrobond® one component glob top epoxies are designed to meet the most stringent demands from the COB industry like low Thermal Coefficient of Expansion (CTE), excellent capillary action to fill in between bonding wires, low ionic contents to prevent corrosion with good thermal stress resistance.

With a good range of viscosities and thixotropy to select from, these glob epoxies have been proven to meet the bare die encapsulation requirement and processability.

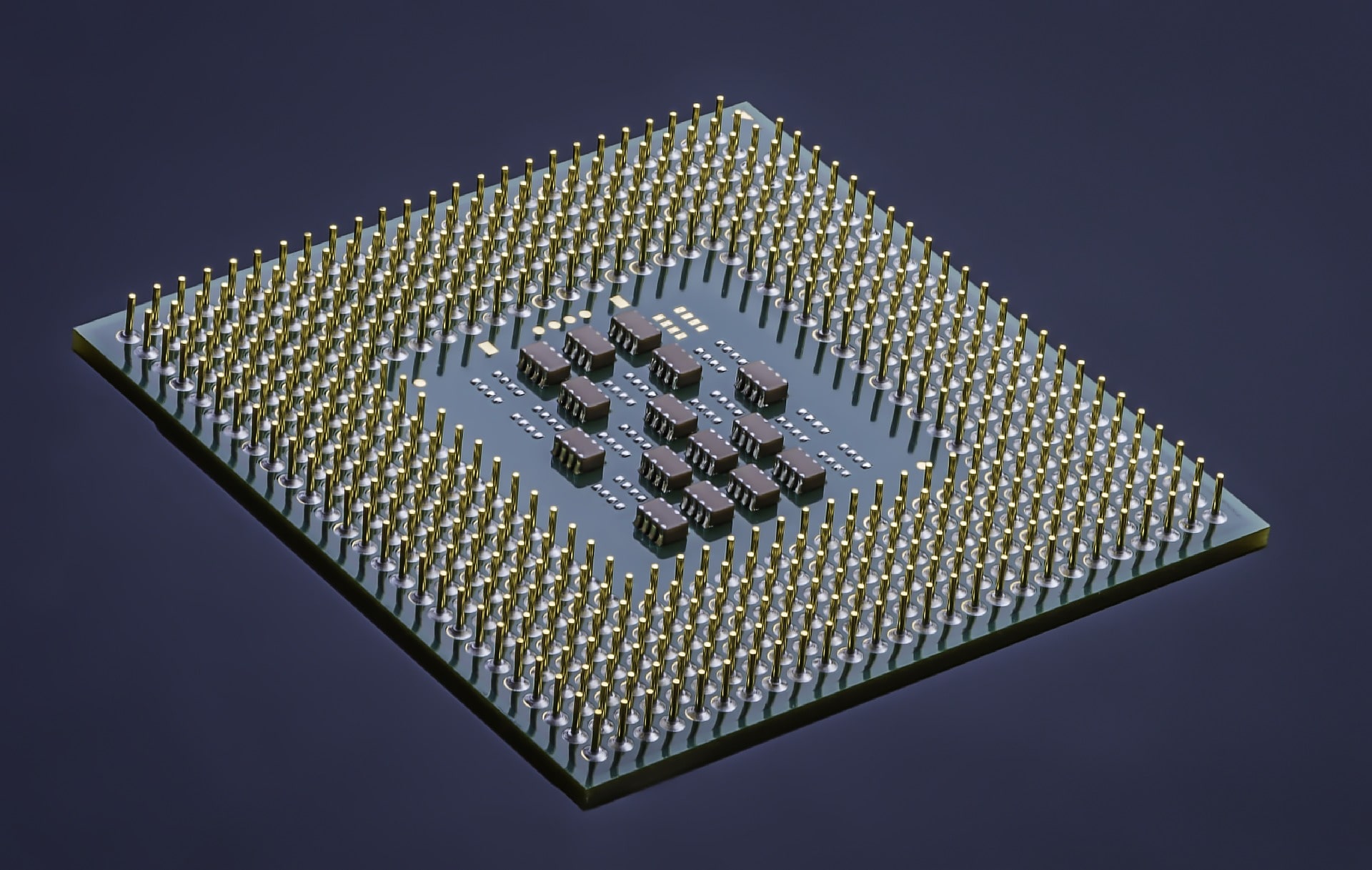

Vitrobond® Underfill Epoxy