Thermal Management Compounds

With enhanced and innovative thermal management compounds like greases (silicone and non-silicone), paste, pad, gap fillers, and heat-dissipating adhesives have enabled the electronic and semiconductor industries to design and produce microchips, mobile devices, telecommunication equipment, and wearable devices with faster connectivity and performance due to better heat management from the range of thermal management products.

Using its proprietary engineering technology, Timtronics is the leading global manufacturer of Non-Silicone based of thermal interface management and with a range of high performance, reliable thermal silicone greases, paste, liquid gap fillers, pads, and thermal potting encapsulants.

With more than 50 years of experience in the research, development, and production of thermal management compounds and applicable for major electronics and O.E.M corporations using proprietary technology and engineering expertise, Timtronics' products have been designed into thousands of applications and help guarantee the performance, integrity, survivability, and maintainability of communications equipment, automotive, radars, aircraft, missiles, spacecraft, computers, fire control systems, and industrial electronics.

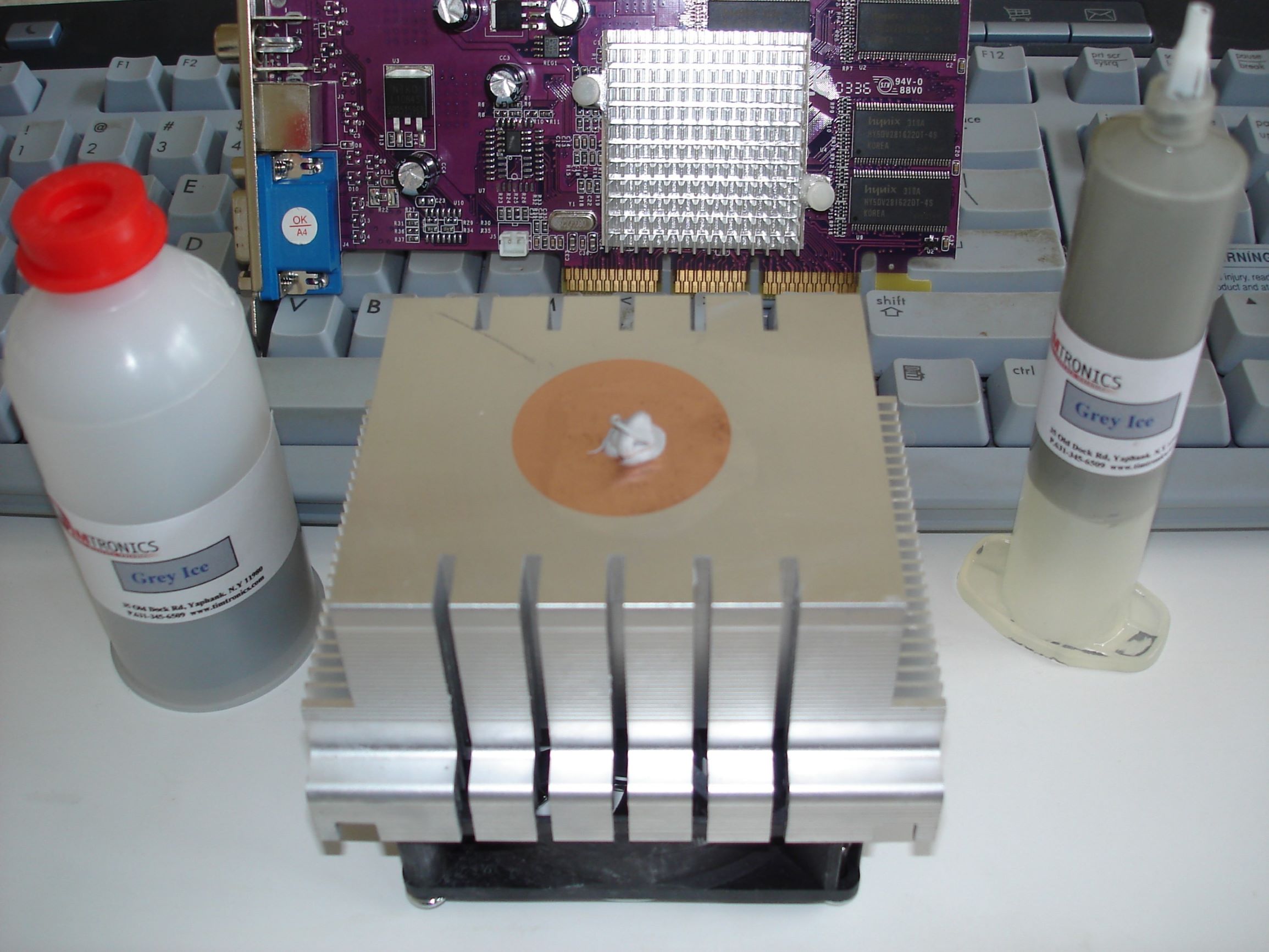

Thermal Greases

Thermal Greases & Paste

When it comes to heat management systems of heat sinks, thermistors, CPU & IGBT, the offering of Timtronics' thermal grease technology provides high thermal conductivities, minimum bond-line thicknesses, and surface wetting. With high-performance thermal greases, it keeps the operating devices and system cool and uninterrupted from overheating or disruption in thermal upswing during operation.

An extensive range of grease is available in Silicone & Non-Silicone formulations to cater to different industries' specifications. Thermal greases are further designed for easy application, screen printable and to offer low cost, low thermal interface resistance for superior thermal transfer. Available in the following categories:

Thermal Gels / Putties

Thermal Putties

Non-Silicone, One Part - No-Cure Type.

Thermally Conductive, Form-In-Place Dispensable Gap Fillers

TIM-PUTTY is ‘Ultra Soft” and highly conformable one part, paste type, Non-Curetype gap filler. Its “ultra-soft” consistency assures efficient heat transfer between delicate parts where minimum pressure can be tolerated. This Form-in-place gap filler is ideal for applying any thickness with little or no stress. It is designed to provide a thermal solution for the recent trends of integrating higher frequency electronics into smaller devices. TIM-PUTTY easily forms and adheres to most surfaces, shapes, and sizes of components with very low compression force. Non-Silicone formulas avoid silicone contaminations to delicate devices. It can be easily dispensed from cartridges or pails using the pneumatic dispenser.

TIM-LGF Series

Silicone, Cure Type Dispensable Liquid Gap Fillers

TIM-LGF are thermally conductive liquid gap filler materials formulated to provide a balance of cured material properties, highlighted by “gel-like” modules and a good compression set or memory. This material is available in thermally conductive & electrically insulating, one part or two-part, room or elevated temperature curing systems. Form-in-place gap fillers are ideal for applying any thickness with little or no stress.

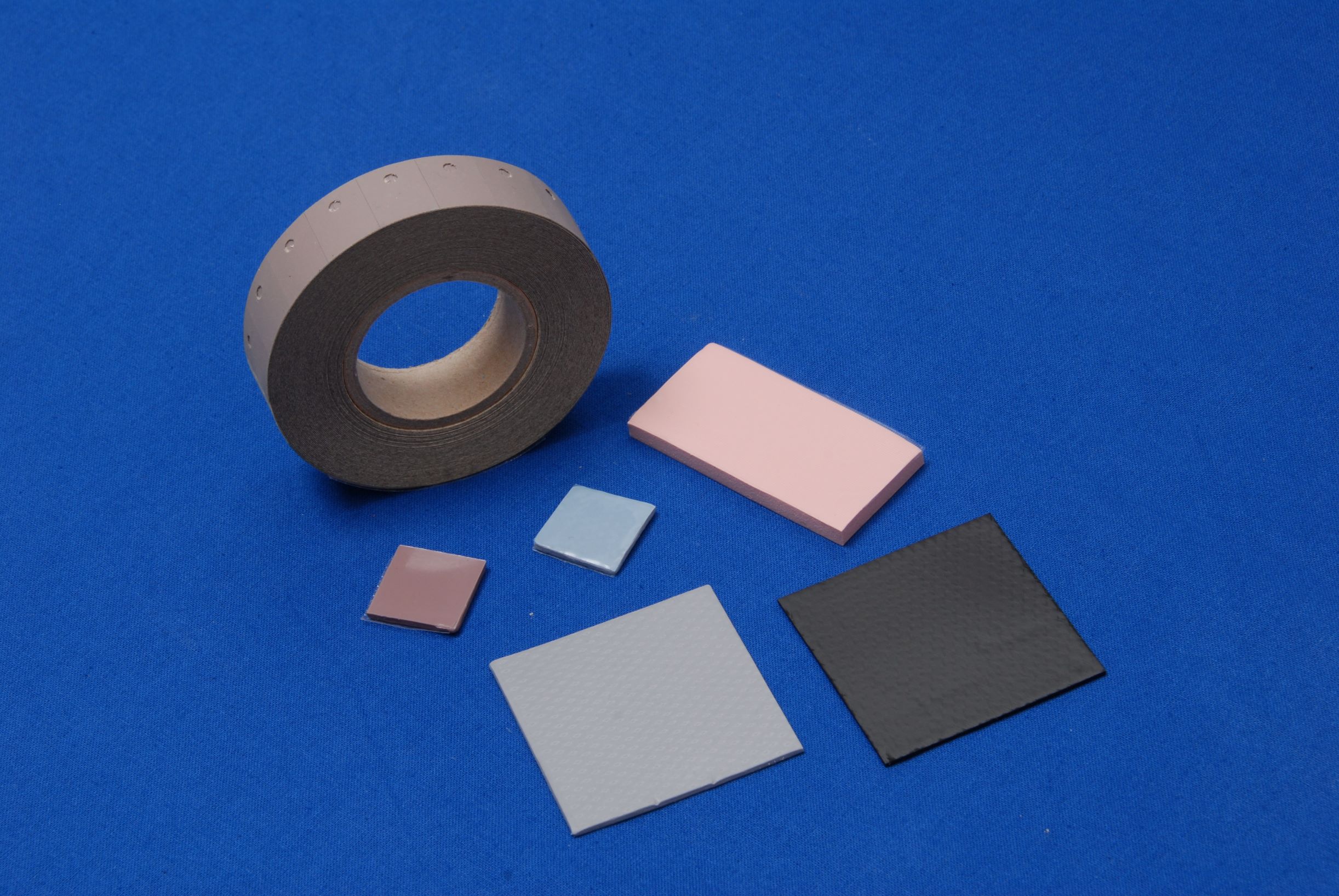

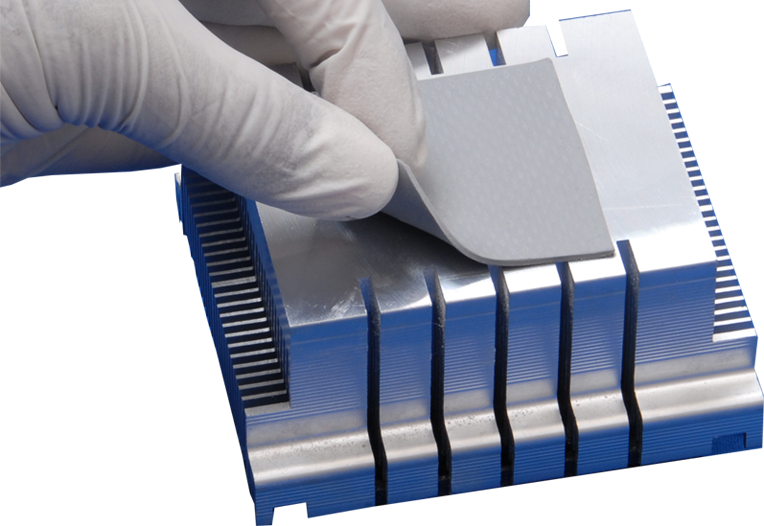

Thermal Gap Fillers & Pads

Thermally Conductive Silicone Gap Fillers

TIM-GAP Series

TIM-GAP series is designed to meet the industry’s growing need for interface material with high conductivity and greater conformability for easier application. Electrically isolating property allows its use in applications requiring isolations between heat sinks and high voltage, bare leaded devices. Available in Silicone and Non-Silicone formulas, thermal conductivity up to 16 W/mºK

P Series are extremely soft, gel type products,highly conformable thermal interface gap filler designed to meet industry’s rapidly growing need for interface material with high thermal conductivity and conformability for low stress applications.

Thermally Conductive Silicone Pads

TIM-PAD Series

TIM-PAD is a family of thermally conductive and electrically insulating silicone pads. They are clean, production-friendly, and efficient alternatives to mica, ceramics, or grease and will provide superb protection against damage due to deformation, shock, or vibration. Available with or without adhesive for easy handling and installation.

Thermal Epoxies and Potting

Thermally Conductive Epoxies Adhesives

TIM-800 series

TIM-800 series are thermally conductive, electrically insulating epoxies engineered with highly conductive ceramic fillers and non-silicone resins. They are designed for the demanding needs of die-attach heat sink bonding and surface mount applications. Rapid heat transfer properties eliminate hot spots and the low epoxy shrinkage factor minimizes the risk of damage to fragile components, resulting in increased operating efficiencies. Available in one part, two parts, heat curable and room temperature cure systems.

One Part Thermally Conductive Epoxies

Two Part Thermally Conductive Epoxies

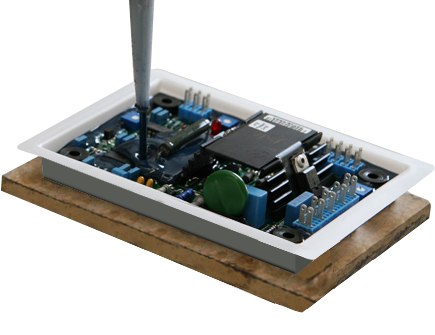

Thermally Conductive Silicone Potting Compounds

TIM-PC Series

Thermally Conductive, two parts, low viscosity potting compound that cures at room temperature to a soft pliable rubber. Will cure in deep sections. Designed to achieve primerless adhesion to many substrates, including metals, plastics, and ceramics. The excellent electrical properties make it a candidate material for both high and low voltage electrical assemblies.

Thermally Conductive Potting Compounds

TIM-PC Series

TIM-PC series are pourable, filled Silicone Free epoxy resin or silicone resin systems offering excellent heat transfer, high voltage insulation, low exothermic and minimum shrinkage. These compounds transfer heat rapidly, thereby eliminating hot spots and increasing the operating efficiency of most encapsulated devices. The low shrinkage design feature minimizes risk of damage to fragile components.