Types of Methacrylate Adhesives

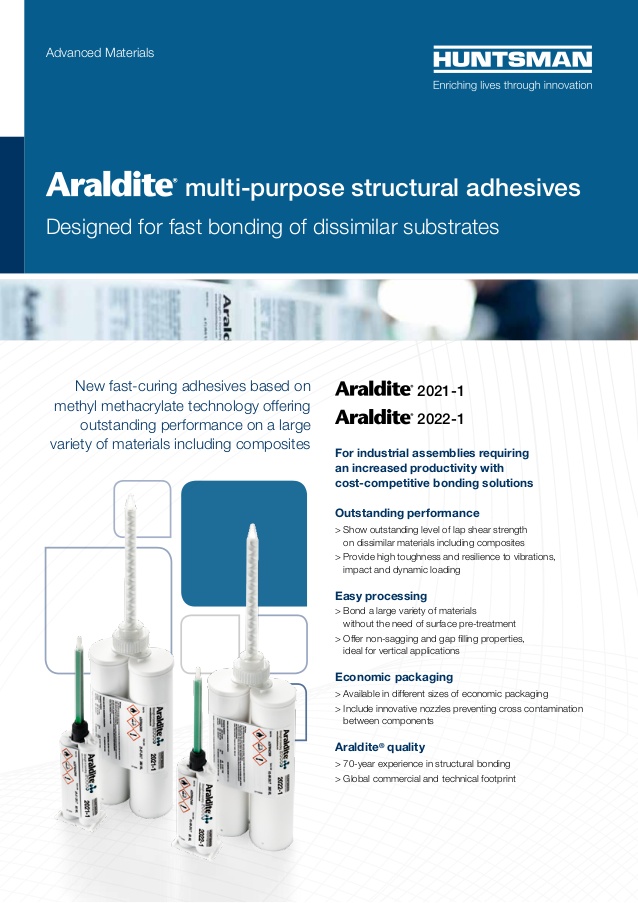

Standard Grade

The standard range of Methacrylate Adhesives (MMA) has very rapid strength build-up once the resin and activator are mixed spanning between 3 - 20 minutes. With Araldite 2021-1, Araldite 2022-1, Partite 7300 & Partite 7301, these MMAs will develop exceptional structural bonding strength, excellent thermal and chemical resistance when fully polymerised which makes it ideal for production environment where speed, ease of use and strength are crucial.

Flexible & Toughened Grade

A new generation of Methyl Methyacrylate Adhesives (MMA) especially developed to fulfill requirements for high flexibility with elongation and rubber toughened properties to allow for severe stress bonding applications. It has the ability to bond dissimilar materials and providing the same bonding integrity needed by the industries. This range of MMA has good gap-filling ability due to its high viscosity and thixotropic properties making it ideal for vertical application without any sagginess.

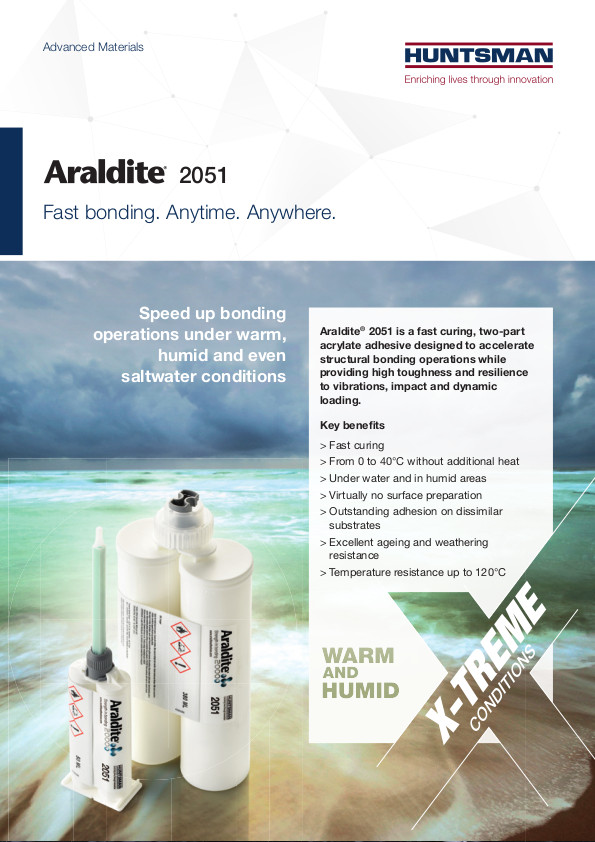

Ultra Fast & High Temperature Grade

Araldite 2050 & Araldite 2051 are ultra-fast curing Methyl Methacrylate Adhesives that are designed for extreme weather conditions and still retain their robustness and bonding strength integrity. As with all other MMAs, it bonds to most similar substrates like metals, composites, and plastics with high toughness and resilience to vibrations, impact and dynamic loading.

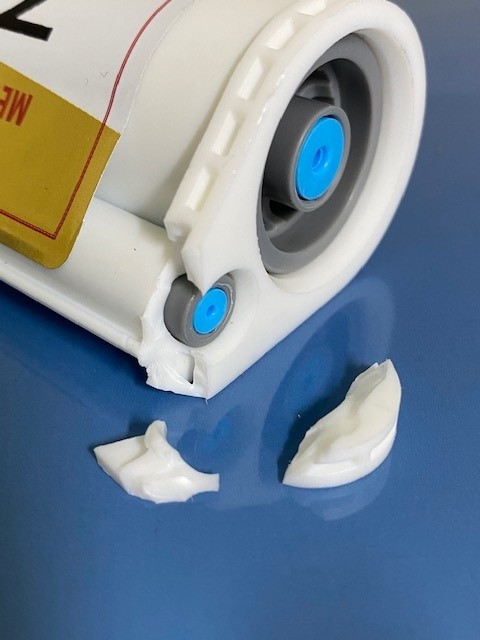

No Mix Methacrylate Adhesive Grade

Agomet No Mix Methacrylate Adhesives are solvent-free reactive acrylic systems, i.e. the strength of the adhesive (cohesion) itself is built through a chemical reaction. In 2-component types, this process is started by mixing the components thoroughly. The mixture's low initial viscosity ensures thorough spreading over the surface, an important pre-condition for final adhesion. As the reaction progresses, the viscosity increases until the adhesive are no longer free-flowing. Once the working time of the mixture is exceeded, it can no longer be applied properly, yet the chemical reaction continues. The final strength of the the bonded joint is reached after a number of hours or days, depending on the adhesive used, whereas the assembled parts can be handled earlier

Methacrylate Adhesive For PP, PE & PA

Bonding special plastic materials with Low Surface Energy (LSE) like Polypropylene (PP), Polyethene(PE), Polyamide (PA or Nylon/Teflon), Thermoplastic Olefin (TPO), and those plasticizer filled plastics that are greasy in appearance will be difficult and there are no known adhesives available that can perform the adhesion effectively.

In order to bond all these Low Surface Energies materials, either it has to be treated by way of applying high voltage arching like corona plasma discharge on the surface before introducing any suitable adhesives or to apply with the latest development of a special formulation of KA Series methyl methacrylate adhesive (MMA) formulated by Everwide Chemical Company.

These unique adhesives have the ability to bond and adhere strongly to all these LSE substrates like PP, PE, PA, and TPO after going through the course of curing. This KA series of MMA cures at amber temperature, has high shear strength, no volatile organic content (100% solventless), no surface treatment required, and able to resist chemicals and water.