Types of Structural Adhesives

2 Component Structural Epoxy & Polyurethane

Araldite® 2000 Core Range

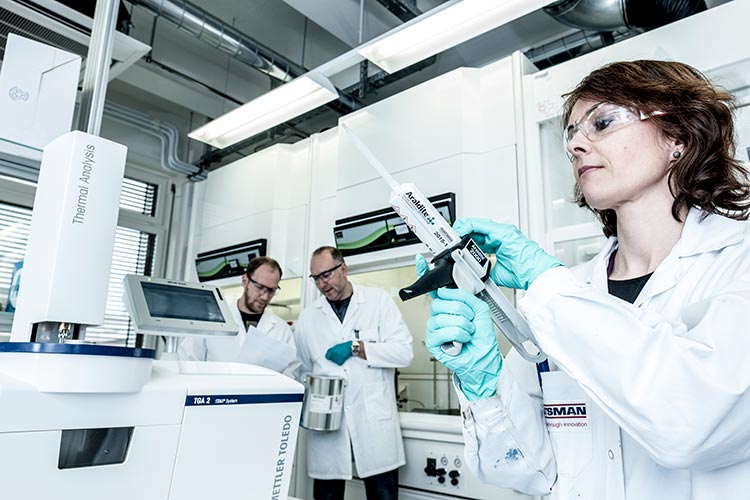

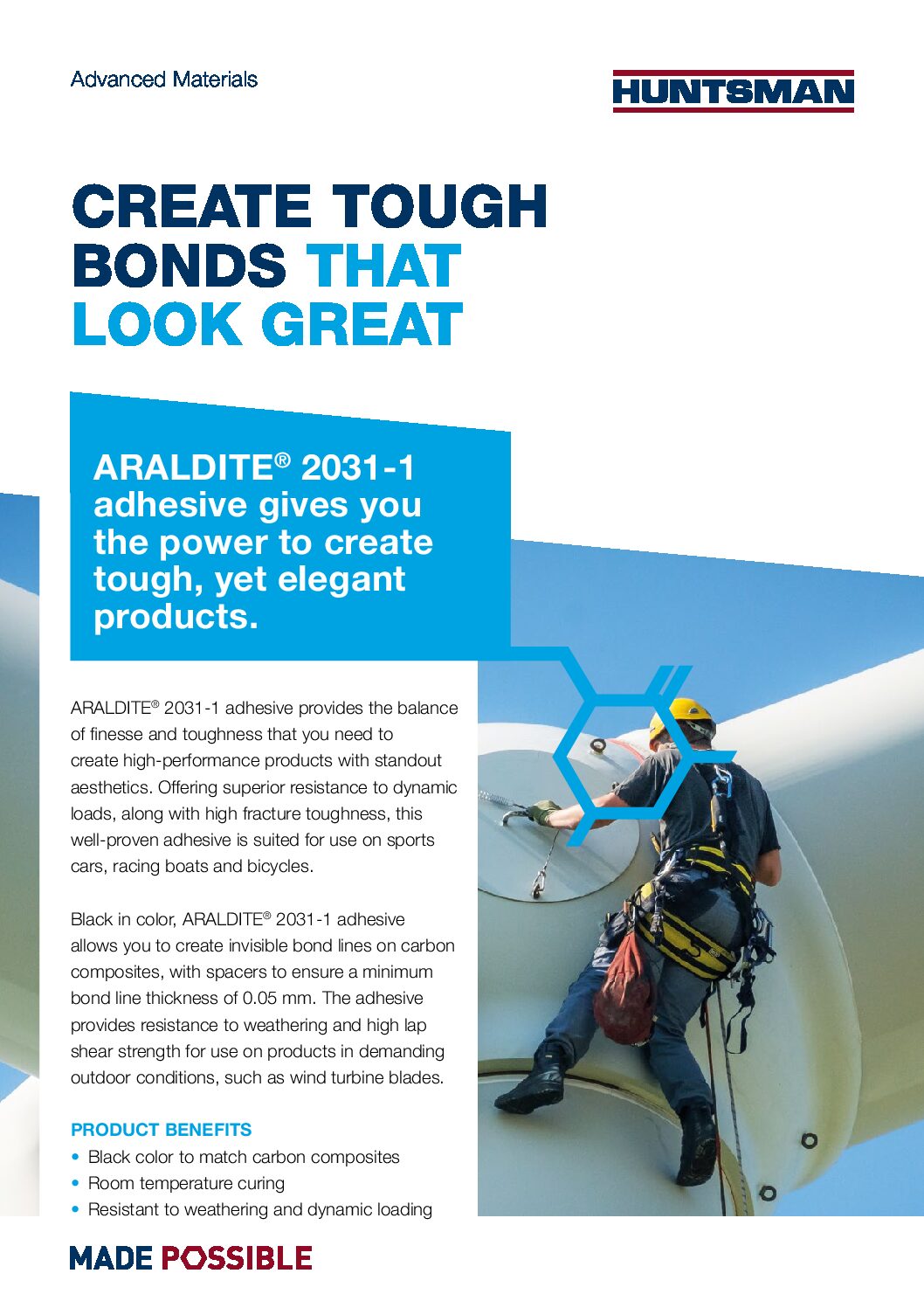

Araldite® 2000 series of Core Range Adhesives are made of nine types of adhesives that are applicable in diverse applications spanning from advertising signage to airplane assembly purpose. These 2 component structural adhesives packed in convenient dual-pack cartridges or bulk packagings are able to bond similar and dissimilar materials substrate with very high lap shear strength and ability to withstand extreme temperature cycles, chemical and impact resistance are available in different viscosities and setting times that can be selected to suit the required application.

Araldite® 2000 with its nine reliable adhesives to choose from, can simplify your product selection when planning a new project. Using these well-tested adhesives, backed up by Huntsman's expert development support, you improve predictability, accelerate time to market and keep your project within budget.

Araldite® Industrial & Engineering Adhesives

Araldite® Industrial Adhesives range has an extensive of adhesives that are preferred and used by industrial, aerospace, electronic, construction and even consumer due to its high bonding performance, chemical, weather resistance and long term reliability. Huntsman Advanced Materials maker of Araldite® is a leading global supplier of synthetic and formulated polymer systems for customers requiring high-performance materials which outperform the properties, functionality and durability of traditional materials.

Epic Resin - Epoxy & Polyurethane Adhesives

Epic Resins is a leading supplier of premium all-purpose adhesives, formulated with a wide range of characteristics and chemistries. It has developed and manufactured epoxies and polyurethanes in multiple formulations for over 60 years and has a reputation for quality work, fast turnaround, and cost-effective pricing. Epic Resins formulates and manufactures epoxy resin and polyurethane adhesives for general purpose industrial use. The range of adhesives includes low viscosity epoxy resin and urethane adhesives that flow into intricate areas, as well as epoxy paste adhesives and thixotropic polyurethane adhesives designed not to sag or run on vertical surfaces.

Vitrobond - 2 Component Structural Epoxy

Vitrobond 2 component epoxies are state of the art adhesive technology system that develops exceptionally high lap shear strength for bonding most type of substrates like, metals, engineering plastics, fibreglass, composite, wood, and rubbers. When fully cured, these epoxies have working temperature performance, withstand most industrial mild chemicals, has good weather elements resistance and some with good thermal conductivity. These 2 component epoxies are available in a range of pot life, colour, work-life and viscosities and packed in easy to use dual pack cartridge.