Structural Sealants

Structural silicone sealants are moisture curing polymers aka Room Temperature Vulcanise (RTV) adhesive that takes in the surrounding humidity to polymerize and form a tough, flexible, and temperature resisting rubber compound. These polymeric sealants are formulated with 1 or 2 component systems that will either cure with surrounding moisture or by way of a catalyst tin to form the polymerization effect.

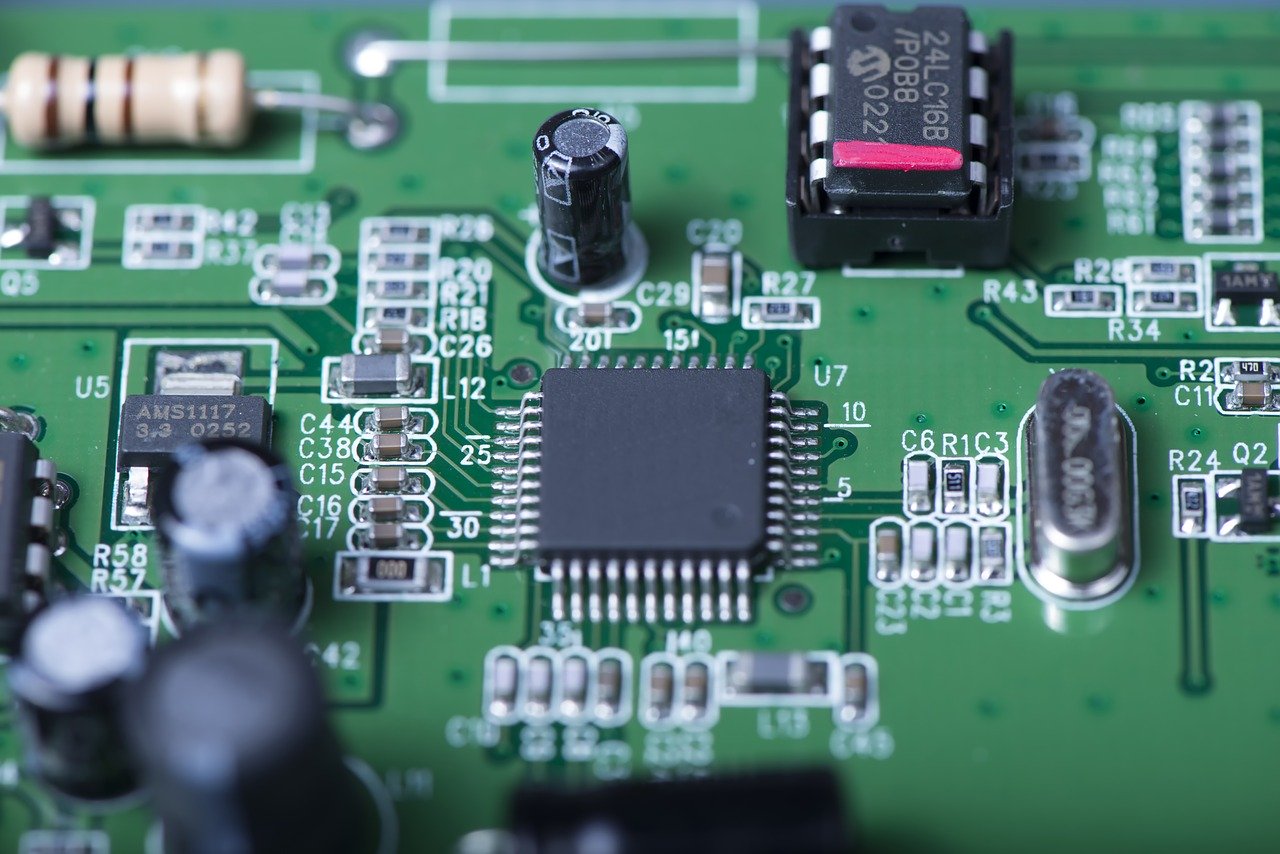

These specialised silicone sealants are widely accepted by the industries like construction, electronics, automotive, solar panel, glass and window installation, and many more applications that require structural sealing and bonding purpose. The cured properties are very robust due to its low Glass Transition Temperature (TG) that gives its flexible nature at ambient condition, high serviceable temperature resistance, anti-UV, good electrical resistance, and highly versatile for use due to its ease of application and cure condition. The types of structural sealants chemistries structural that is being widely used in the industries include

- Silicone Sealant that is either made up of Acetoxy / Acetic, Oxime/Neutral based

- Polyurethane Sealant.

All these polymeric sealants when fully cured will yield high bonding strength, minimal shrinkage, and long-term durability when exposed to different environmental and operating conditions.

High Temperature Silicone Adhesive

Intek XTS 320 Silicone Selant

Certified to Nato Stock Classification: NSN 6850-99-519-6905