GREASE & LUBRICANT

Grease & Lubricant

DeoxIT® range of Grease is used in the most demanding applications. Manufactured in semi-solid form for use as a combination cleaning, deoxidizing, protecting and lubricating preparation. These products contain a synthetic base oil in a lithium complex thickener system. Grease protects against oxidation (galvanic corrosion) and is free of mineral acids, sulphurs, alkalis, and other noxious components aggressive to metals. DeoxIT® Grease improves the performance of electrical contacts and mechanical components that require precise lubrication.

Industry Uses & Applications

DeoxIT® Grease & Lubricant

Good lubrication, good abrasion, excellent wear resistance, excellent pressure resistance, excellent oxidation (galvanic corrosion) protection, high dripping-point characteristics. Superior moisture resistance. Resist washout and excessive dilution by water assuring all-weather protection. Excellent mechanical stability. Safe on plastics.

- Precision Lubrication

- Oxidation & Corrosion Protection

- Wear & Pressure Resistance

- High Dripping Point

- Extreme Temperatures, -40ºC to 260ºC

DeoxIT® L260 & L260D

- High Stress/High Loads

- Shock Load Protection

- Low Wash Out & Oil Separation

- Corrosion, Wear & Water Resistant

- Extreme Temperatures, -40 to 240ºC

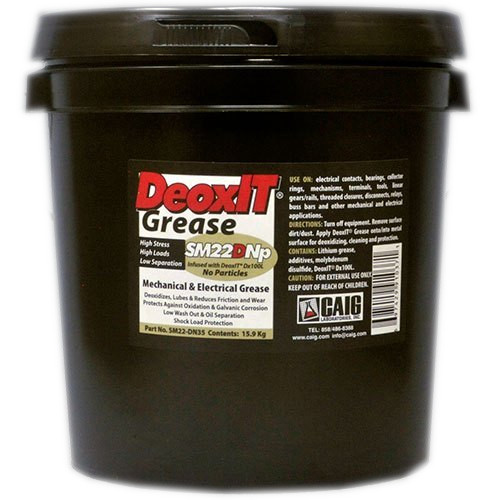

DeoxIT® SM22 & SM22D

- High Stress/High Loads

- Shock Load Protection

- Low Wash Out & Oil Separation

- Corrosion, Wear & Water Resistant

- Extreme Temperatures, -40 to 240ºC

DeoxIT® L27-MM

- High Stress/High Loads

- Shock Load Protection

- Low Wash Out & Oil Separation

- Corrosion, Wear & Water Resistant

- Extreme Temperatures, -40 to 240ºC

DeoxIT® L27-ME

DeoxIT® Grease - With or Without Particles

Soft, thixotropic grease for lubrication and protection of surfaces. Maximum lubrication for relatively clean surfaces. NEW!

Soft, thixotropic grease for lubrication and protection of surfaces. Maximum lubrication for relatively clean surfaces. The infusion of DeoxIT® D-Series D100L into the formulation provides an additional film on the metal surface to dissolve corrosion, improve conductivity and provide a moveable/flexible protective film on the surface.

Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use when aluminum metals are involved to assist break up corrosion. Use in areas that two contacts will not touch and possibly short. Example: aluminum rails, bolts, connectors.

Graphite provides excellent lubricating and heat transfer characteristics. Use where lubrication is vital and heat absorption and dissipation is important.

Use when you need particles (non conductive) to assist in oxide break up and you require good lubrication and abrasion. Quartz particles assist in breaking up oxidation and corrosion. Quartz is nonconductive.

Use when heat transfer, lubrication and assistance is needed in breaking up oxides and corrosion. Finer particles than the copper.

Use when lubrication is essential. Teflon particles are nonconductive.

DeoxIT® Grease Type L260 & L260NP (No Particles)

CAIG’s DeoxIT® L260 Grease is a lithium grease with unique additives to enable it to adhere and stay on the surfaces it is applied to. It has the tenacity to stick to surfaces. Additional additives allow it to displace moisture, prevent oxidation and corrosion and provides superior lubrication and protection. DeoxIT® L260 Grease’s unique properties allow it not only to be used on mechanical devices – also electrical devices and equipment; such as high powered switches, disconnects, connectors, relays and exposed connections in severe environments.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260 Grease Spray

Use: For mechanical and electrical devices and equipment that require precise lubrication.

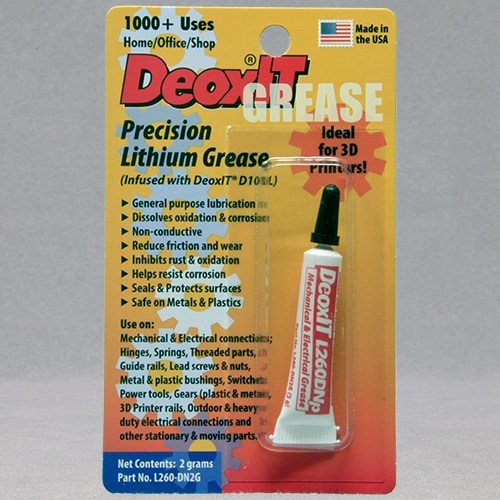

DeoxIT® L260Np Grease

(No Particles)

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Np Grease

(No Particles)

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Np Grease

(No Particles)

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Np Grease

(No Particles)

DeoxIT® Copper Particles - Types L260Cp

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Cp Grease

Copper Particles (L260-C1)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Cp Grease

Copper Particles (L260-C8)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Cp Grease

Copper Particles (L260-C8TP)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Cp Grease

Copper Particles (L260-C35)

DeoxIT® Aluminum Particles - Types L260Ap

Particles: Aluminum – Use when aluminum metals are involved to assist break up corrosion. Use in areas that two contacts will not touch and possibly short. Example: aluminum rails, bolts, connectors.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Ap Grease

Aluminum Particles (L260-A1)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Ap Grease

Aluminum Particles (L260-A8)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Ap Grease

Aluminum Particles (L260-A8TP)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Ap Grease

Copper Particles (L260-C35)

DeoxIT® Graphite Particles - Types L260Gp

Particles: Graphite – Graphite provides excellent lubricating and heat transfer characteristics. Use where lubrication is vital and heat absorption and dissipation is important.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Gp Grease

Graphite Particles (L260-G1)

Particles: Graphite– Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Gp Grease

Graphite Particles (L260-G8)

Particles: Graphite – Graphite provides excellent lubricating and heat transfer characteristics. Use where lubrication is vital and heat absorption and dissipation are important.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Gp Grease

Graphite Particles (L260-G8TP)

Particles: Graphite– Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Gp Grease

Graphite Particles (L260-G8)

DeoxIT® Quartz Particles - Types L260Qp

Particles: Quartz – Use when you need particles (non conductive) to assist in oxide break up and you require good lubrication and abrasion. Quartz particles assist in breaking up oxidation and corrosion. Quartz is nonconductive.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Qp Grease

Quartz Particles (L260-Q1)

Particles: Quartz – Use when you need particles (nonconductive) to assist in oxide break up and you require good lubrication and abrasion. Quartz particles assist in breaking up oxidation and corrosion. Quartz is nonconductive.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Qp Grease

Quartz Particles (L260-Q8)

Particles: Quartz – Use when you need particles (nonconductive) to assist in oxide break up and you require good lubrication and abrasion. Quartz particles assist in breaking up oxidation and corrosion. Quartz is nonconductive.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Qp Grease

Quartz Particles (L260-Q8TP)

Particles: Quartz – Use when you need particles (nonconductive) to assist in oxide break up and you require good lubrication and abrasion. Quartz particles assist in breaking up oxidation and corrosion. Quartz is nonconductive.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260Qp Grease

Quartz Particles (L260-Q8)

DeoxIT® Graphite/Quartz Particles - Types L260GQp

Particles: Graphite/Quartz – Use when heat transfer, lubrication, and assistance is needed in breaking up oxides and corrosion. Finer particles than copper.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260GQp Grease

Graphite/Quartz Particles (L260-GQ1)

Particles: Graphite/Quartz – Use when heat transfer, lubrication, and assistance are needed in breaking up oxides and corrosion. Finer particles than copper.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260GQp Grease

Graphite/Quartz Particles (L260-GQ8)

Particles: Graphite/Quartz – Use when you need particles (nonconductive) to assist in oxide break up and you require good lubrication and abrasion. Quartz particles assist in breaking up oxidation and corrosion. Quartz is nonconductive.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260GQp Grease

Graphite/Quartz Particles (L260-GQ8TP)

Particles: Graphite/Quartz – Use when you need particles (nonconductive) to assist in oxide break up and you require good lubrication and abrasion. Quartz particles assist in breaking up oxidation and corrosion. Quartz is nonconductive.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260GQp Grease

Graphite/Quartz Particles (L260-GQ35)

NO Particles – Type L260DNp – Infused with DeoxIT® Dx100L

Particles: None

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DNP Plus Grease Spray (L260S-N10D)

Particles: None

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DNP

L260-DN8TP (No particles)

Particles: None – infused with DeoxIT® Dx100L

Use: For mechanical and electrical devices and equipment that require precise lubrication.

.

DeoxIT® L260DNP

#L260-DN1 (No Particles)

Particles: None – infused with DeoxIT® Dx100L

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DNP

#L260-DN360 (No particles)

Particles: None – infused with DeoxIT® Dx100L

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DNP

#L260-DN2G (No Particles)

Particles: None – infused with DeoxIT® Dx100L

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DNP

#L260-DN35 (No particles)

Particles: None – infused with DeoxIT® Dx100L

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DNP

#L260-DN8 (No Particles)

Copper Particles – Type L260DCp – Infused with DeoxIT® Dx100L

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DCp, #L260-DC1 (Copper particles)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DCp, #L260-DC8 (Copper particles)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DCp, #L260-DC8TP (Copper particles)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DCp, #L260-DC360 (Copper particles)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DCp, #L260-DC360 (Copper particles)

Graphite Particles – Type L260DGp – Infused with DeoxIT® Dx100L

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DCp, #L260-DC1 (Copper particles)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DCp, #L260-DC8 (Copper particles)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DCp, #L260-DC8TP (Copper particles)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.

DeoxIT® L260DCp, #L260-DC360 (Copper particles)

Particles: Copper – Use when you require particles (conductive) to assist in oxide and corrosion breakup and good lubrication. Copper is conductive. Use in areas that two contacts will not touch and possibly short. Example: disconnect switches or large connectors and relays.

Use: For mechanical and electrical devices and equipment that require precise lubrication.